Designing a Clear Topic Structure for Your UNS

Why Topic Structuring is Key to Scaling and Optimizing Your UNS

Topic structuring is not just a technical concern when building a high-performance Unified Namespace (UNS) for manufacturing environments; it's a strategic design choice that can determine the system's scalability, efficiency, and overall effectiveness.

A well-structured topic hierarchy is critical in manufacturing, where vast amounts of data flow from sensors, machines, and systems. By organizing your topics correctly, you can streamline data flow, simplify scaling, and make your system more manageable as your operations grow.

In this post, we'll explore the significance of topic structuring for your UNS, outline why it's essential for scalability and performance, and share best practices for designing a robust topic hierarchy that can evolve alongside your business.

# Why Topic Structuring is Crucial for Your UNS

When building a UNS for manufacturing environments, MQTT is one of the most popular and preferred choices due to its lightweight, efficient, and scalable design. MQTT’s publish-subscribe model is perfect for handling the real-time, high-volume data flow in factories, where machines, sensors, and devices constantly generate information. However, while MQTT is a powerful tool, how you structure your topics plays a pivotal role in ensuring that your UNS is scalable and efficient.

Manufacturing operations often experience rapid growth. The sheer number of sensors, machines, and production lines increases over time, and so does the complexity of the data. MQTT topics are hierarchical, which means they follow a tree-like structure with levels separated by a forward slash (/). This hierarchical structure can mirror the physical layout of your factory floor, providing a logical, scalable framework for your data.

For example:

/factory/line1/machine1/temperature

This topic structure indicates that the data comes from machine1 on line1 of your factory, specifically from a temperature sensor. The structure is intuitive because it directly reflects the factory’s layout. Adding more machines, sensors, or production lines is straightforward as your factory grows.

For instance, as your factory adds a second production line, you can add topics like:

/factory/line2/machine1/temperature/factory/line2/machine1/vibration/factory/line2/machine2/temperature

This hierarchical system scales seamlessly as you add more machines, sensors, and production lines without creating unnecessary complexity.

A well-structured topic hierarchy improves the performance of both the network and edge devices. When monitoring or data analysis systems subscribe to topics, they can choose the data they need. This means they are not overwhelmed by unnecessary traffic, which could otherwise strain network bandwidth and device processing power.

For example, imagine a maintenance team only needs to monitor the temperature of machines in line 1. With a clean topic structure, they can subscribe to:

-

/factory/line1/machine1/temperature -

/factory/line1/machine2/temperature

By filtering the data, they avoid receiving irrelevant data, such as vibration readings from other machines or temperatures from machines on different production lines. This reduces network load, ensures more responsive performance, and prevents overloads on edge devices.

A well-organized topic structure makes maintenance and troubleshooting much more efficient. When equipment malfunctions or a sensor starts reporting erroneous data in a smart factory, the ability to pinpoint the issue quickly is crucial. With a hierarchical topic system, you can easily trace the problem to a specific machine, sensor, or production line.

For instance, imagine a temperature sensor on machine 3 in line 2 reporting abnormal values. A topic like:

/factory/line2/machine3/temperature

Immediately indicates the affected machine and production line. This clarity lets your team act quickly, reducing downtime and improving system reliability.

Without a clear topic structure, identifying and diagnosing problems can become time-consuming, leading to extended downtime and inefficiencies.

As new equipment, sensors, or production lines are added to the factory, a well-structured topic system helps onboard new engineers, technicians, and operators easily. A clear hierarchy provides a visual map of the system, making it easier for new users to understand the architecture and begin working with it quickly.

# Designing a Topic Structure for Your UNS

Before you start collecting data in your UNS, it’s essential to design your topic structure. While it might seem like a small step, it’s the foundation of your system. Taking the time to plan will save you significant time and effort down the road. More importantly, it gives you a clear, high-level view of your entire factory, which is crucial for scaling effectively.

First, think about the key components of your factory. For example, you might have different plants or production lines in a manufacturing setting. There will be machines or devices within each production line that produce data. Then, you’ll have various data points coming from sensors on these machines, such as temperature, humidity, or pressure.

By organizing your topics around these components, you’re setting up a structure that’s easy to scale.

Next, remember that MQTT topics are hierarchical, so think of them like a tree. At the top of the tree, you’ll have the broadest categories (like plants or regions). As you go down, you’ll get more specific, with production lines, machines, and then individual data points like sensor readings. The key is to keep things logical so that you can locate the data you need quickly. This organization lets you promptly expand your system later by adding new plants, lines, or machines without disrupting the entire structure.

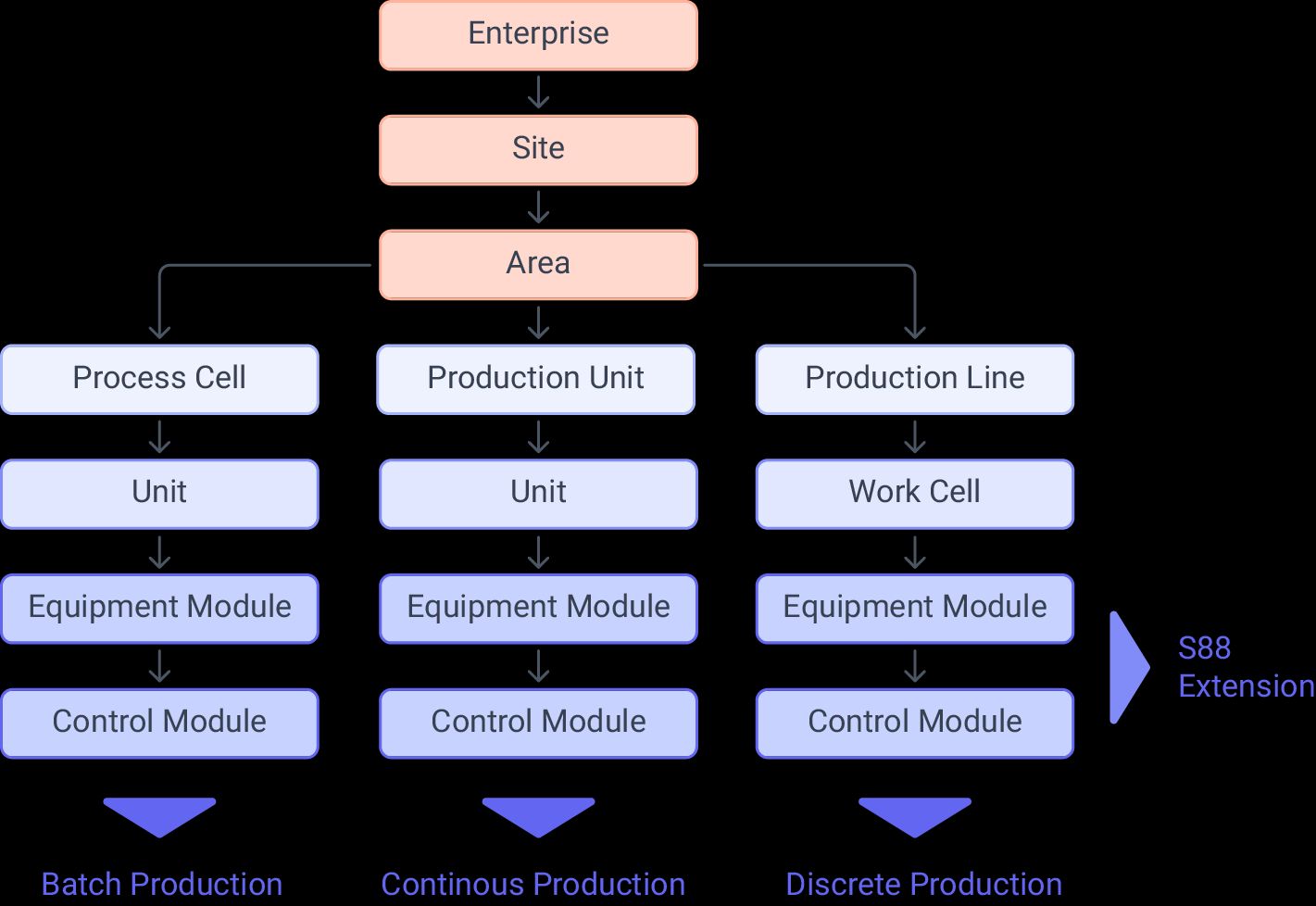

The concept of structuring topics logically and hierarchically draws from a well-known framework in manufacturing: ISA-95. ISA-95 is a standard that defines a hierarchical model for organizing and managing manufacturing systems. It divides operations from the company level to individual machines, providing a clear structure for system management.

Here’s a brief breakdown of the ISA-95 levels and how they can be translated to MQTT topics:

- Level 0 – Physical Devices and Control

This is where the physical data originates: sensors, actuators, and devices directly interacting with machinery and production lines. These are typically represented as devices in your MQTT topic structure.

Example Topics:

-

/plantA/productionLine1/machineB/sensor/temperature -

/plantA/productionLine1/machineB/sensor/pressure -

/plantA/productionLine2/machineC/sensor/humidity

At this level, you're dealing with specific machines and sensors. The topic name clearly defines the device type (e.g., "sensor") and the type of data it generates (e.g., "temperature"). This structure makes tracking sensor data easy for each machine or production line.

- Level 1 – Control Devices and Systems

This level represents the control systems that operate the machinery and manage the data flow. These systems include PLCs, SCADA systems, or other control devices that manage real-time operations.

Example Topics:

-

/plantA/productionLine1/machineB/PLC/status -

/plantA/productionLine1/machineB/PLC/mode -

/plantA/productionLine2/machineC/SCADA/alerts

Topics at this level might focus on the status and control functions of the machines. Separating control systems like PLCs or SCADA ensures that operational data (e.g., machine modes or alerts) is distinct from raw sensor data. This approach ensures that each system component can be monitored and managed independently.

- Level 2 – Monitoring and Supervisory Control

At this level, systems monitor and manage operations. They might include higher-level systems that oversee the production lines, collect data from multiple PLCs, and trigger alerts or analyses based on predefined criteria.

Example Topics:

-

/plantA/productionLine1/supervisor/alerts -

/plantA/productionLine1/supervisor/performance -

/plantA/productionLine2/supervisor/utilization

Here, you might aggregate data from several control devices (like PLCs) and provide higher-level insight into the overall system. For example, a "performance" topic could aggregate sensor data to monitor the efficiency of a production line, while "alerts" might be used for system-wide warnings.

- Level 3 – Manufacturing Operations Management

This level encompasses managing the overall production process, such as scheduling, production orders, and resource management. This is often where MES (Manufacturing Execution Systems) comes into play.

Example Topics:

-

/plantA/productionLine1/MES/productionOrder -

/plantA/productionLine2/MES/scheduling -

/plantB/productionLine1/MES/inventoryStatus

The data becomes more abstract at this level as you deal with business logic, production orders, and scheduling systems. For example, the "productionOrder" topic could track orders for specific products, while "inventoryStatus" could provide data on material availability for each production line.

- Level 4 – Enterprise Resource Planning (ERP)

The highest level in the ISA-95 hierarchy is focused on enterprise-wide resource planning, financials, and decision-making processes. ERP systems integrate with manufacturing systems to provide broader business insights.

Example Topics:

-

/enterprise/ERP/inventory/overview -

/enterprise/ERP/sales/orders -

/enterprise/ERP/production/metrics

At the ERP level, topics reflect cross-plant business data like inventory, order management, or performance metrics. These are less granular than lower levels and provide decision-makers with high-level insights into the health of the overall business.

# Best Practices for Managing Your Topic Structure

As your UNS scales, following some essential best practices will ensure your topic structure remains efficient, secure, and easy to manage.

- Maintain Clear Documentation:

First and foremost, maintaining clear documentation is key. A well-documented topic hierarchy is a reference point for everyone involved in the system—from developers and engineers to system administrators. This documentation should outline the naming conventions, the purpose of each topic, and how new issues should be added. Without it, there's a risk of inconsistency creeping into your system, especially as new data streams and devices are introduced. An apparent, organized reference ensures your team can efficiently navigate and expand the system without confusion.

- Ensuring Consistency in Naming and Structure:

Using clear, descriptive names for each topic and sticking to a consistent naming pattern across your system is essential for long-term success. A well-defined naming convention ensures that everyone involved—whether developers, engineers, or system administrators—can easily understand the purpose of each topic. Navigating your UNS becomes intuitive when topics are consistently named, and troubleshooting issues is much easier.

For instance, avoid vague or overly generic names like /sensor1/data, which don’t offer much context. Instead, adopt more descriptive, hierarchical names that reflect the actual source and nature of the data, such as /plantA/productionLine1/machineB/temperature. A consistent structure not only enhances system readability but also ensures scalability.

- Keep Topic Names Simple and Avoid Special Characters:

While it’s essential to have descriptive topic names, they should also be simple and easy to use. Long topic names can make working with your UNS quickly and efficiently harder. Also, avoid using spaces or special characters, which might cause compatibility issues with some MQTT brokers or clients.

- Perform Regular Topic Cleanup and Expiration:

Next, don’t overlook the importance of topic cleanup and expiration. Over time, unused or obsolete topics can accumulate, adding unnecessary complexity and overhead to the system. Left unchecked, these stale topics can lead to unwanted confusion. It’s important to regularly audit the issues in your UNS, archiving or removing those no longer needed. While some MQTT systems support automatic topic expiration, implementing manual checks as part of your routine system maintenance is still a good practice. You’ll also want to manage the use of retained messages carefully. While they can help provide the latest state to new subscribers, overuse or misuse can lead to outdated information circulating across the system. Be mindful about which topics should retain data and ensure they are updated or cleaned up regularly.

- Implement Robust Access Control:

Access control is essential in managing a large-scale UNS. The hierarchical structure of MQTT topics naturally supports role-based access control (RBAC), allowing you to assign permissions based on topics. This ensures users and devices only access the data they need.

For example, engineers might only need access to machine-level sensor data, while plant managers require broader visibility into performance metrics across production lines. Additionally, you can restrict which devices can publish data on specific topics, ensuring only authorized systems send critical updates.

By defining clear access rules, you enhance security, maintain data integrity, and ensure that your UNS can scale efficiently as your organization grows.

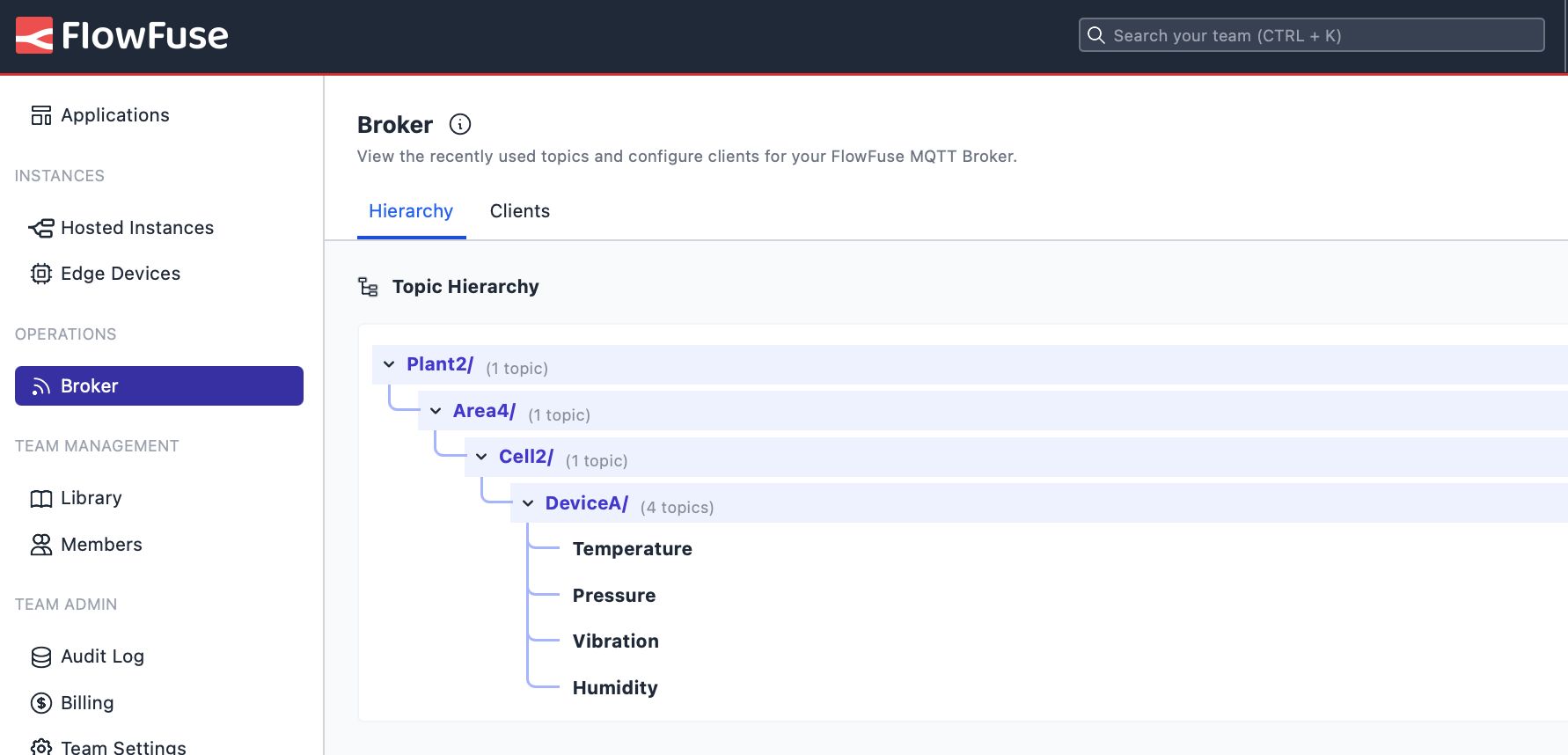

# Effortless MQTT and Topic Management with FlowFuse

FlowFuse is more than just a low-code platform; it’s a game-changer for building and scaling your UNS. By seamlessly integrating MQTT, FlowFuse empowers you to connect, manage, and scale your industrial data systems efficiently.

FlowFuse's built-in MQTT broker gives you high-performance data handling without additional infrastructure overhead. The platform also features an interface for managing MQTT clients with access control for topics and an intuitive Topic Hierarchy View, which provides a real-time, visual representation of your entire MQTT topic structure. This makes organizing, monitoring, and managing your topics easy, ensuring clarity and consistency as your system grows.

What truly stands out is FlowFuse's ability to handle both legacy and modern industrial protocols, effortlessly bridging the gap between old and new systems. Whether adding new devices, integrating data streams, or scaling to thousands of devices, FlowFuse gives you the flexibility, scalability, and security you need to optimize your UNS at every step.

FlowFuse doesn’t just help you manage topics—it streamlines collaboration, enhances system performance, and accelerates your journey toward a fully integrated, future-proof UNS.

Looking to simplify your UNS management? Unlock the full potential of your data architecture with FlowFuse.

Sign Up for FlowFuse Now to Get StartedWritten By:

Published on:

Related Articles:

- Building a Unified Namespace (UNS) with FlowFuse

- The Death of Point-to-Point: Why You Need a Unified Namespace

- Why UNS needs Pub/Sub

- Managing MQTT Connections at Scale in FlowFuse

- Why FlowFuse is the Complete Toolkit For Building UNS?