Node-RED as a No-Code EtherNet/IP to S7 Protocol Converter

Beginner tutorial for using Node-RED as free industrial protocol converter

Frequently in industrial automation, there's a need for two devices that use different protocols to communicate with each other, requiring protocol conversion.

In this tutorial, we present a mock scenario where Node-RED is used to enable an Allen Bradley PLC, which uses ethernet/IP, to communicate with a Siemens PLC, which uses S7, using a no-code solution. This example is geared toward beginners and assumes that the end-user knows how to use PLCs, but may be using FlowFuse or Node-RED for the first time.

# Premise

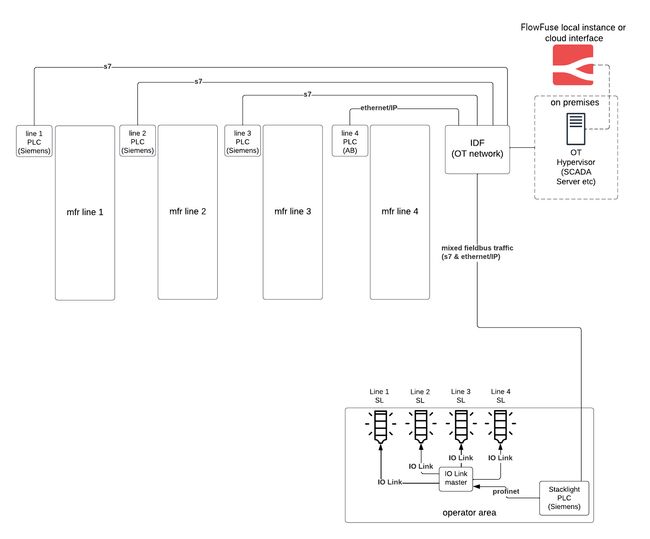

The figure above shows the layout of a mock production facility. Inside this facility, operations suggested adding stack lights as an extra visual aid for operators to get a quick status of its 4 conveyor lines, avoiding the need to constantly monitor the HMI/SCADA displays.

Engineering has suggested adding a siemens S7 1200 PLC with an IO link connection to 4 stacklights, with each line PLC sending basic status information to the stacklight PLC to control the stack light outputs.

Line 1-3 PLCs are Siemens-based, and can communicate with the stacklight PLC natively over S7. But line 4 is an Allen Bradley PLC that uses ethernet/IP, and can't communicate with the stacklight PLC without some form of protocol conversion.

Traditionally, we'd use protocol gateway hardware, like Anybus or Red Lion, to convert ethernet/IP to S7.

But for this application, we will instead use FlowFuse, a pure software-based approach, to convert ethernet/IP to S7. Let's walk through the process.

# Pre-Requisites and Set Up

# FlowFuse

In addition to our two PLCs, we’ll be using FlowFuse software to serve our Node-RED instance. You can either self-host, on-premise or in the cloud. Or use the managed service FlowFuse Cloud.

In this example, we will be using a self-hosted FlowFuse instance running on Docker.

# Data Treatment on Ethernet/IP PLC

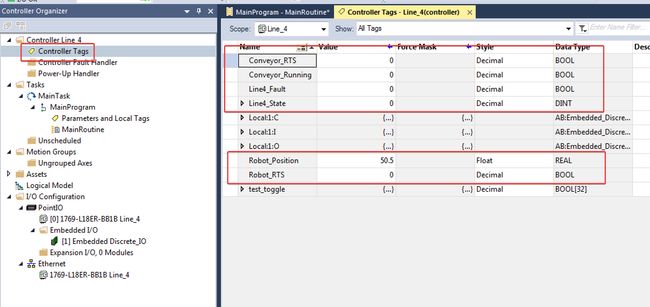

In our Allen Bradley line 4 PLC, we will send some arbitrary tags of various datatypes to the stacklight PLC for illustrative purposes, described in table 1 below -

| Tag | Data Type | Description |

|---|---|---|

| Conveyor_RTS | BOOL | Conveyor Ready to Start |

| Robot_RTS | BOOL | Robot is Ready to Start |

| Robot_Position | REAL | Robot Arm position (degrees) |

| Conveyor_Running | BOOL | Conveyor is running |

| Line4_State | DINT | Line 4 Machine State |

| Line4_Fault | BOOL | Line 4 is faulted |

Table 1 - Line 4 Tags to be sent to Stacklight PLC

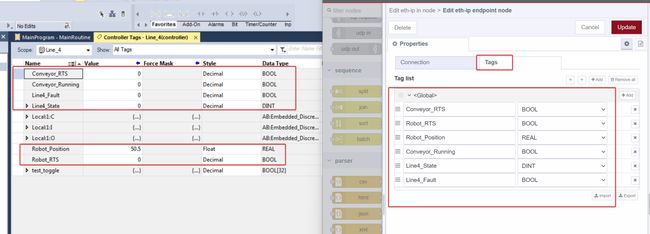

We can send any atomic data type we want, but it must be globally (controller) scoped.

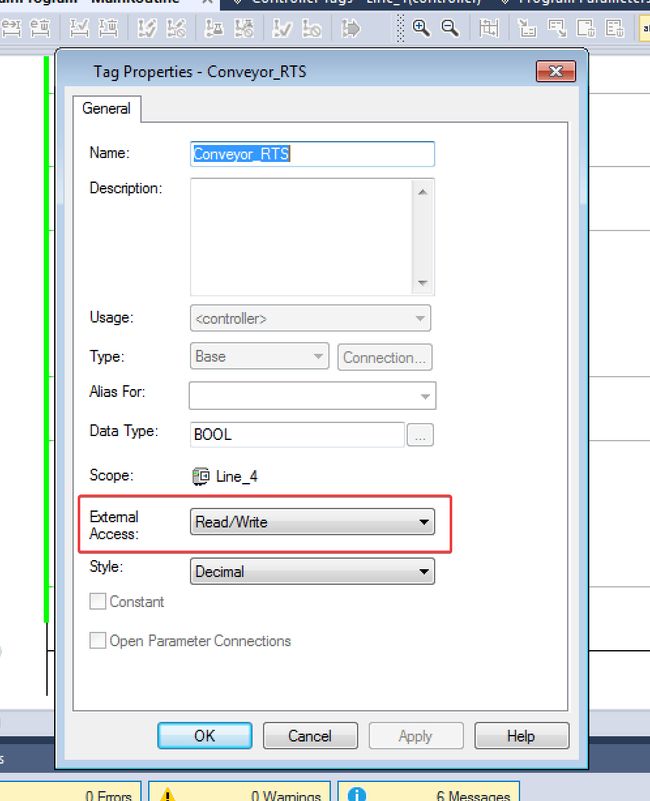

Each tag must also have external read/write access enabled.

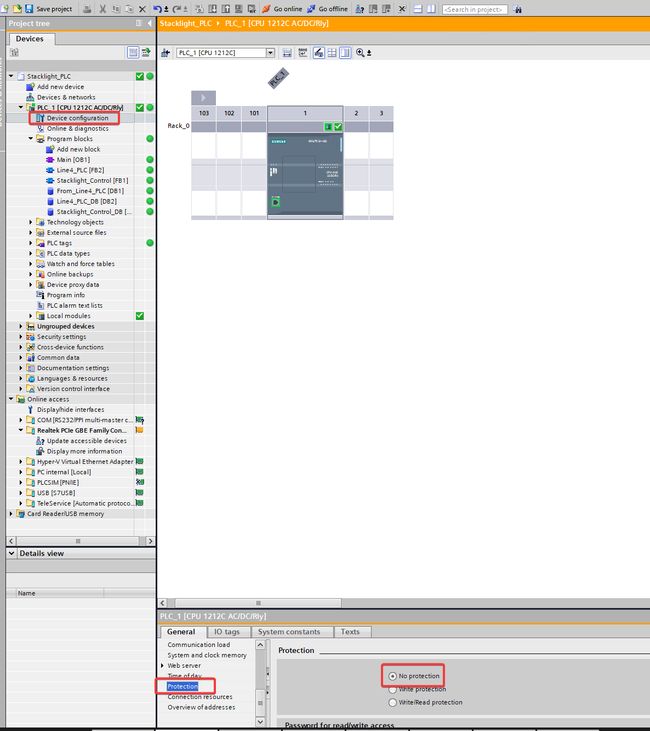

# Data Treatment on S7 PLC

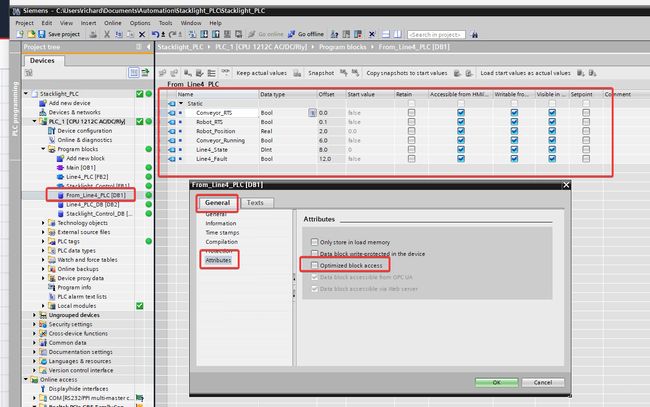

In the Siemens PLC, we have a DB for the data from the Line 4 PLC to be written to.

-

In the DBs attributes, “optimized block access” must be disabled.

-

The tags must be writeable and accessible

-

“No protection” must be set in the CPU properties

-

# Create The Flow

With both PLCs up and running and properly set up to send/receive remote data, we can now create a flow to act as our protocol converter.

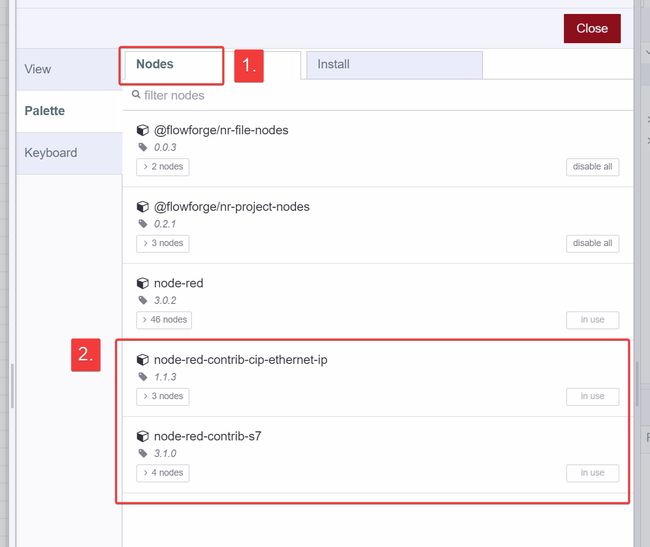

# Install Custom Nodes

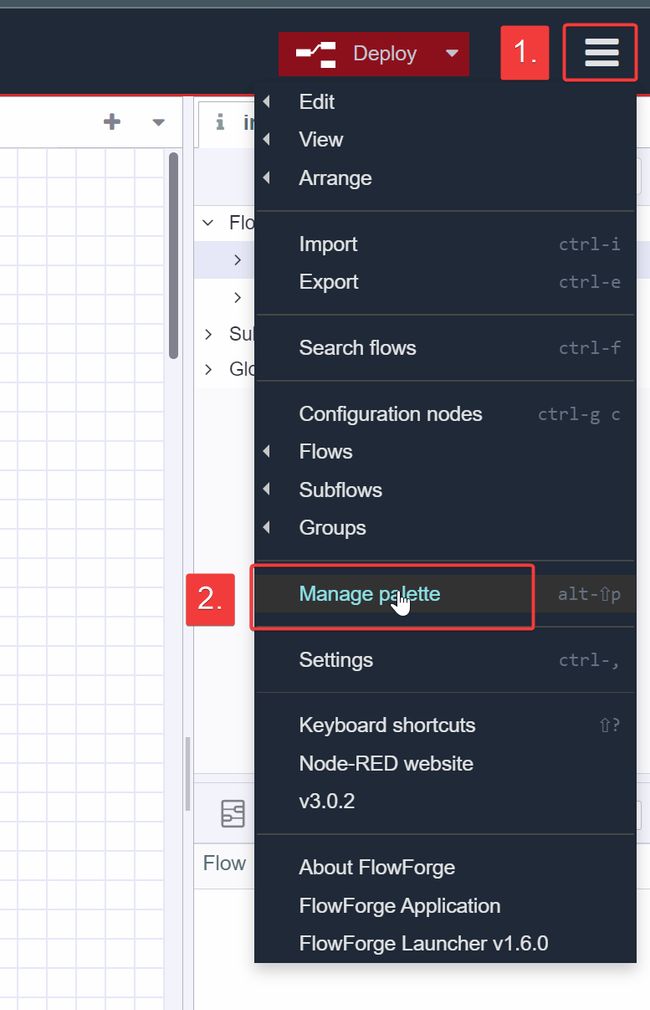

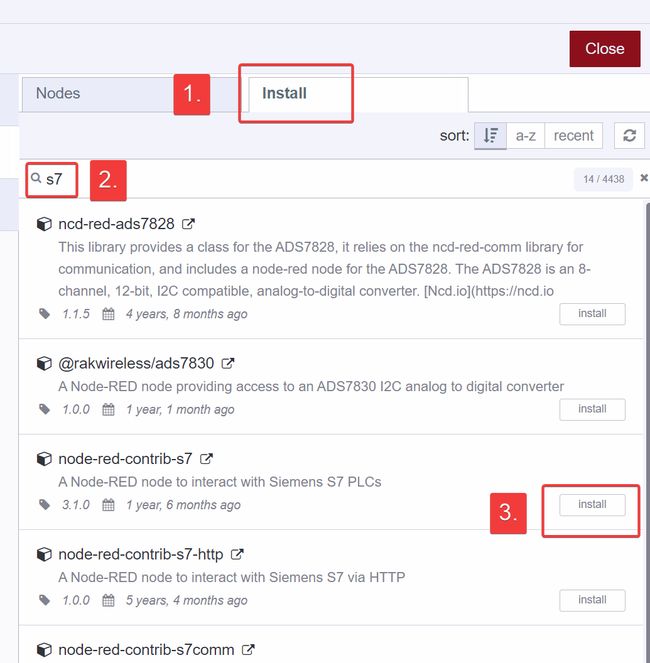

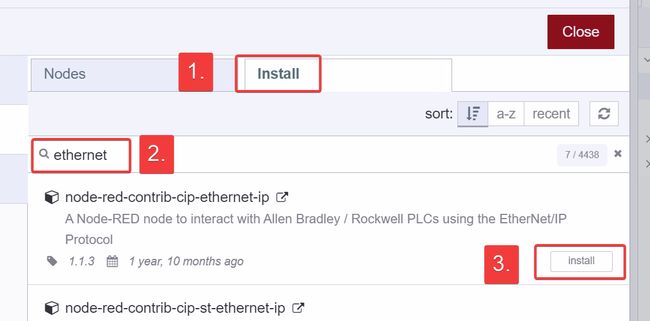

First, we need to add two custom nodes that will give node-red the ability to read/write ethernet/IP and S7 data.

Click the hamburger icon → manage pallette

On the install tab, search for s7 and install the node-red-contrib-s7 node.

Next, search for ethernet and install the node-red-contrib-cip-ethernet-ip node.

nodes tab and confirm both custom nodes have been properly installed.

# Set Up Ethernet/IP Data

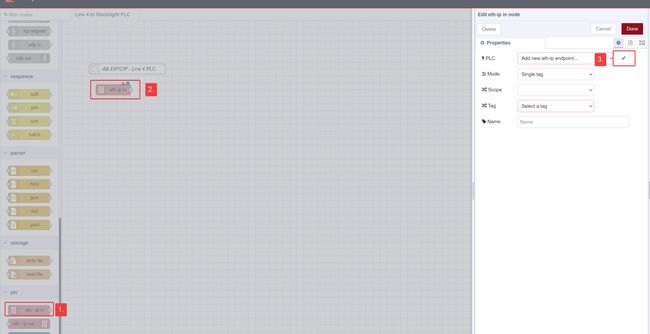

Let’s start by dragging a eth-ip in node onto the pallette. Then add a new endpoint, which will point to our Line4 PLC.

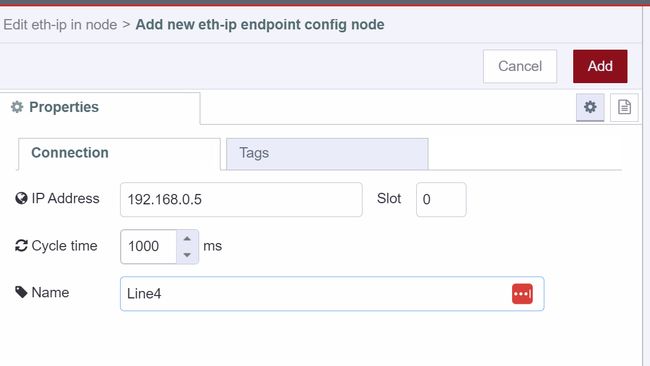

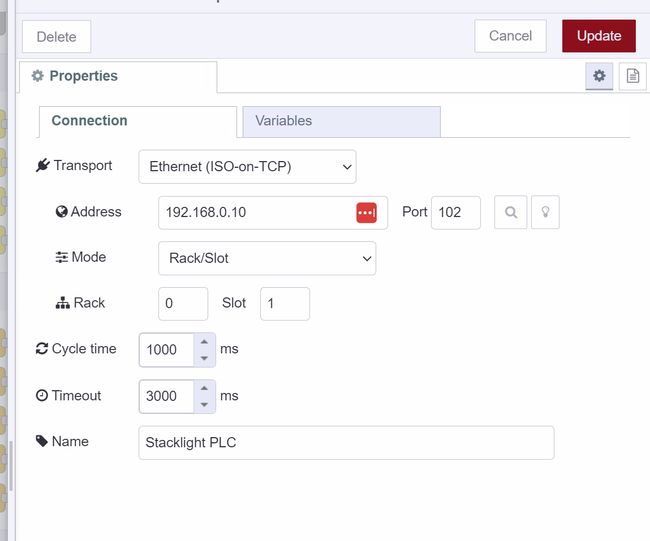

In the endpoint connection properties, the connection information must match the PLC, so set the IP address and CPU slot number appropriately. Also, the default cycle time is 500ms. Depending on your application, polling the CPU at 500ms may be appropriate. But being that this is a simple stacklight, 500ms is unnecessarily fast. So we will change it to 1000ms, which is a more appropriate polling rate for this type of application.

On the Tags tab, populate the tag information to match our Allen Bradley PLC. Then select Update to complete configuration of the eth-ip endpoint.

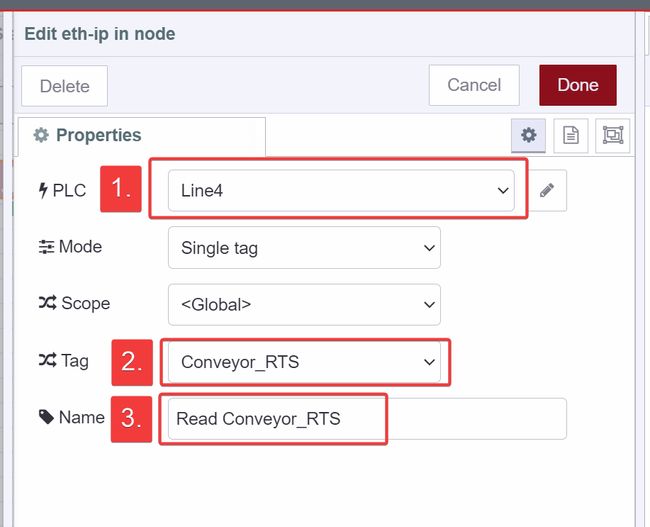

Now that we have our endpoint, let’s finish configuring the eth-ip in node.

-

select the endpoint we just created

-

select the first tag in the drop-down

-

give the node a descriptive name

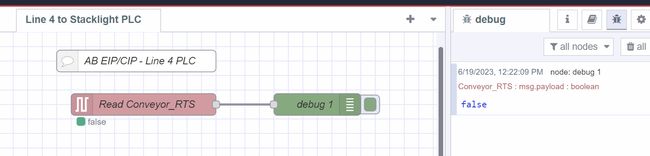

Now let’s set up a quick test to confirm our PLC connection is valid by adding a debug node to the eth-ip in node. Then hit deploy.

- note - you can see we also have a

commentabove the nodes that describes what is happening. This is optional but good practice to help organize and understand your flow.

The output of the debug console did not report any errors so communication appears to be okay.

But just to confirm, let’s toggle the value and see if comes through.

So by toggling the value and see the result, here we confirmed 2 things:

-

We can detect changes in value

-

the

eth-ip innode only sends a message when the value changes, also known as Report by Exception.

Because the eth-ip in node implicitly uses report by exception, and the protocol doesn't rely on contiguous data consistency (unlike modbus, for instance), we can receive our data one tag at a time to keep our flow simple.

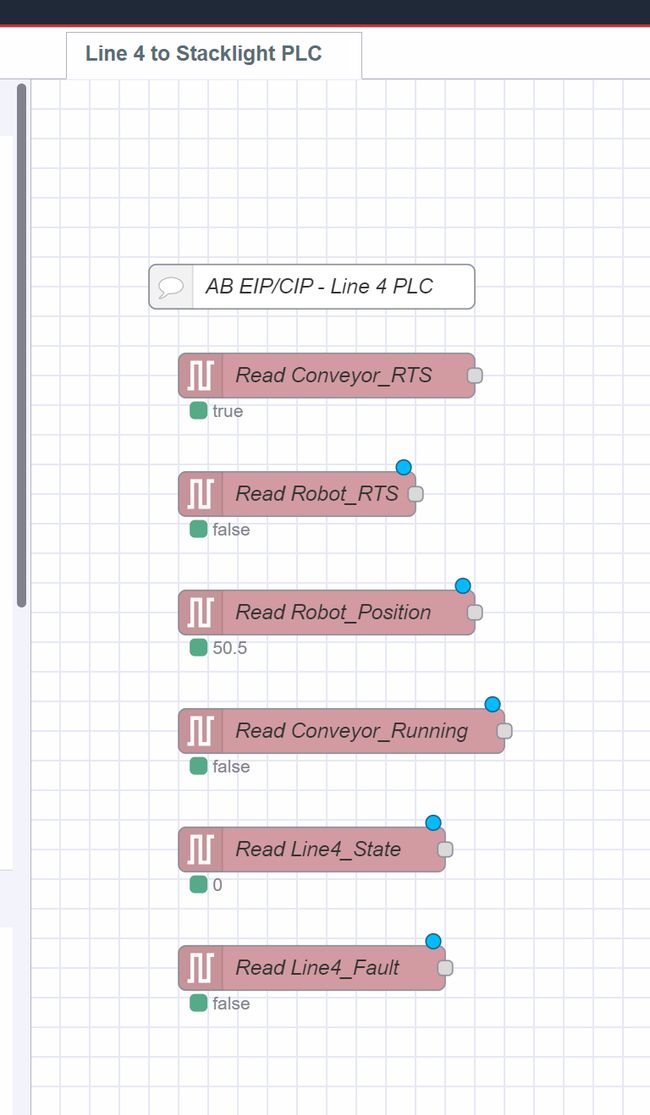

Now we can remove the debug node and add the additional eth-ip in nodes to receive the remaining tags from our Line 4 PLC.

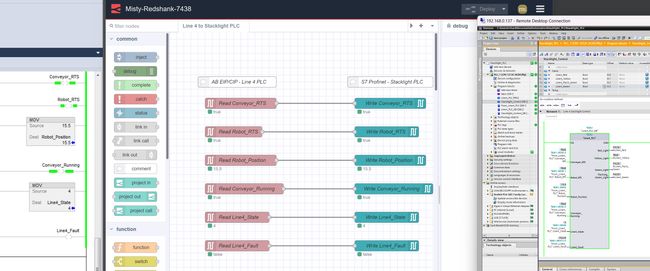

Here’s how the the flow should look at this point.

# Set Up S7 Data

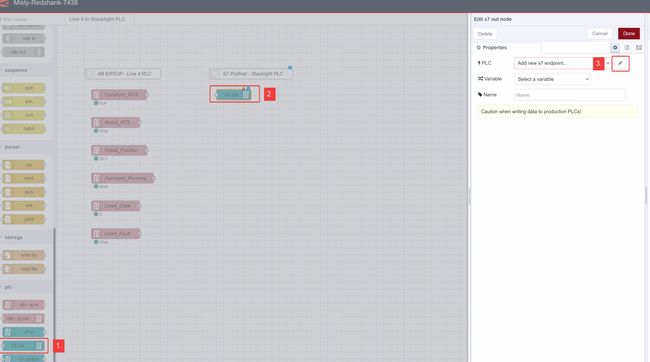

Now we’ll set up the S7 endpoint, using an s7 out node.

Populate the connection properties to match your hardware. The cycle time is updated to 1000ms to match the cycle time of our eth-ip in nodes. You can adjust this value to match your intended application.

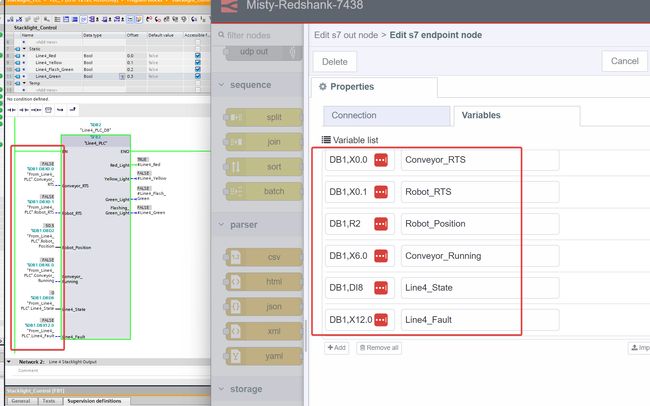

On the Variables tab, some special formatting is required to point to the absolute reference of the tag DB location in the S7 PLC.

For information on how to format S7 absolute tag references in a way the s7 endpoint node is expecting, refer to the node documentation for further information.

For reference, here is an example of how we set the tags in our stacklight PLC example and how it looks in our s7 endpoint.

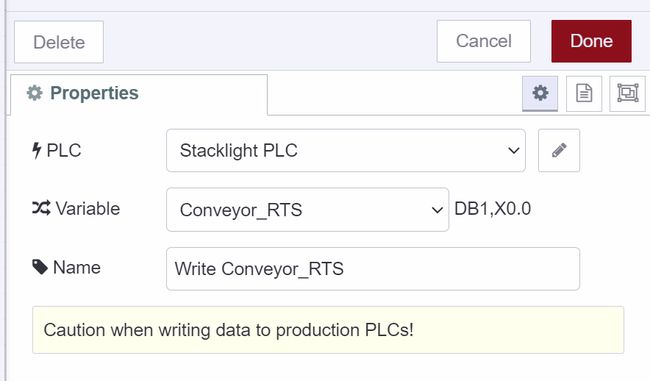

Once the tags are populated we can select our configured endpoint from the dropdown list, point to our first variable, Conveyor_RTS, and give the node a name.

Repeat this process for the remaining tags.

# Test the Conversion

The only thing remaining is to simply wire the nodes together, and confirm the values pass through.

Manipulate the incoming values and confirm the data passes through as expected. Because of the report by exception nature of the eth-ip in node, tag changes should be near instantaneous on the receiving PLC.

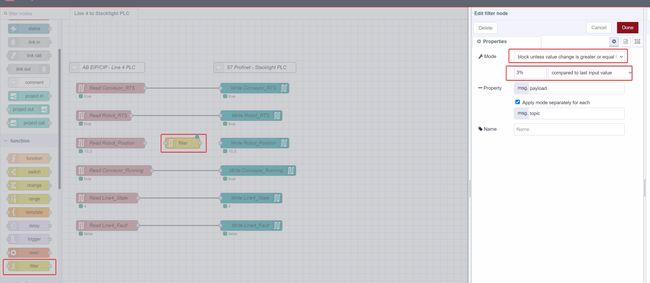

We can stop here, but we can improve this flow by adding a filter node on our REAL data-type, Robot_Position.

# Add Filter to REAL data

Depending on how noisy the REAL data is, which is common with unfiltered 4-20mA field transmitters, and how much granularity you need to capture, it is good practice to add a filter on REAL data to reduce FieldBus traffic coming out of our soft protocol converter.

In the example above, we arbitrarily applied a 3% deadband

to the Robot_Position value, which means that the value must change by greater than or equal to 3% compared to the last input value, or else the data will be discarded before being sent to the stacklight PLC.

You can adjust the deadband to find the right balance for your particular application.

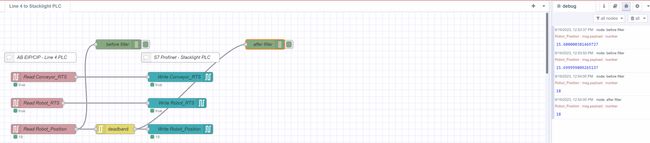

We can see the effect the deadband filter had by adding debug nodes before and after the filter.

As shown above, when Robot_Position changed from 15.6 to 15.6999..., the value was captured on the input of the filter, but was discarded on the output.

When the Robot_Position went from 15.6999 to 18, the filter allowed it to pass as it exceeded the deadband limit we had set.

Use filters to optimize your fieldbus converter network performance, especially if dealing with noisy signals or large quantities of REAL datatypes.

# Conclusion

In this tutorial, we demonstrated how to use Node-RED as a free Ethernet/IP to S7 protocol converter using a simple no-code approach. We showed how to configure PLC tags to be sent remotely using Ethernet/IP, how to configure PLC tags to be received remotely using S7, and how to create the flow to use Node-RED to seamlessly convert incoming PLC data between the two protocols using node-red-contrib-cip-ethernet-ip and node-red-contrib-s7 custom nodes. We also took things one step further and added a filter node to optimize FieldBus network traffic by putting a deadband on REAL data being sent to the receiving PLC.

The end result is a simple to set up, free and performant industrial protocol converter that requires minimal PLC configuration, which allows this application to be applied in non-mission critical production systems with minimal, if any downtime. Additionally, the protocol traffic can be visually observed in real-time for easy trouble-shooting and fault analysis by simply accessing the Node-RED UI.

In later tutorials, we can show ways this simple flow can be extended to add additional capabilities not normally available in traditional off-the-shelf protocol gateways. If you found this tutorial helpful, or have any questions or comments, please leave us a comment and let us know your thoughts.

JSON source code for the flow used in this tutorial is provided below -

Written By:

Published on:

Recommended Articles:

- FlowFuse 2.19: More Powerful AI in Node-RED, Drop-In Blueprints, Memory Monitoring, and Faster Onboarding

- Curated Node-RED Integrations: FlowFuse Certified Nodes 2.0

- Part 2: Building an Andon Task Manager with FlowFuse

- What to Measure on the Shop Floor: Factory KPIs Your MES Should Deliver

- Structuring and Storing Data for Effective MES Integration