What is 5S Checklist: Definition, Benefits, Implementation, and Template

Understand 5S Checklists, Improve Work Area Efficiency, and Start with a Ready-to-Use FlowFuse Template

Manufacturing environments face increasing pressure to eliminate waste, improve safety, and maintain quality standards. Disorganized workspaces contribute to production delays, safety incidents, and quality defects that directly impact operational performance. The 5S methodology addresses these challenges through systematic work area organization, but implementation requires consistent evaluation and measurement. A 5S checklist provides the structured framework necessary to assess, maintain, and improve work area organization standards across manufacturing operations.

Understanding 5S Methodology

The 5S methodology originated in Japanese manufacturing and has become the gold standard for work area organization worldwide. The name comes from five Japanese words that each begin with 'S', representing a systematic approach to creating efficient, safe workspaces:

- Sort (Seiri) means removing everything that doesn't belong in your workspace. This involves ruthlessly eliminating "just in case" items that create clutter and reduce efficiency.

- Set in Order (Seiton) gives everything that remains a logical, designated home based on frequency of use and workflow patterns.

- Shine (Seiso) focuses on cleanliness that reveals problems early. Oil leaks, wear patterns, and safety hazards become immediately visible in clean environments.

- Standardize (Seiketsu) creates consistent procedures so everyone follows identical organizational principles across shifts and departments.

- Sustain (Shitsuke) builds the culture and accountability systems needed to maintain improvements permanently.

The challenge isn’t just understanding these concepts; it’s implementing them consistently across different operations.

What Makes a 5S Checklist Essential

A 5S checklist transforms abstract organizational principles into concrete, measurable actions with specific evaluation criteria. Instead of subjective opinions about workspace organization, teams get objective standards: Is every tool in its designated shadow board outline? Are walkways completely obstacle-free? Can someone new find required materials within two minutes?

Beyond simple evaluation, these checklists serve as training tools for new employees, communication devices between shifts, historical records showing improvement trends, and accountability systems that prevent 5S from becoming another forgotten initiative.

Essential 5S Checklist Items Every work area Needs

While each work environment requires specific evaluation criteria, certain fundamental items should be included in every 5S checklist. Here is a practical framework of 25 questions that you can adapt for your operations.

Sort

- Are workstations free of unnecessary materials, tools, and equipment?

- Have outdated documents and reference materials been removed?

- Are broken or obsolete items properly tagged for disposal?

- Do storage areas contain only frequently used items?

Set in Order

- Is every tool in its designated location with clear identification?

- Are frequently used items positioned within easy reach?

- Are visual management systems (labels, shadow boards, floor markings) clearly visible?

- Can workers retrieve needed items without searching or moving obstacles?

Shine

- Are all surfaces, equipment, and floors properly cleaned?

- Are maintenance schedules current and inspection logs up-to-date?

- Are cleaning supplies readily available and properly stored?

- Are leaks, spills, and abnormal conditions immediately visible?

Standardize

- Are work instructions current, accessible, and consistently followed?

- Do similar workstations follow identical organizational principles?

- Are all team members trained on current 5S standards?

- Are procedures regularly reviewed and updated?

Sustain

- Do workers maintain organizational standards without constant supervision?

- Are team members actively identifying improvement opportunities?

- Do supervisors regularly participate in evaluations and improvements?

- Are 5S achievements recognized and celebrated?

The Real Impact on Your Operations

Companies that implement 5S checklists consistently report dramatic improvements that go far beyond having a tidy workspace. Workers typically spend less time searching for tools and materials once proper organization takes hold. This isn't just about efficiency, it's about frustration levels and job satisfaction too.

Safety improvements often exceed expectations. When everything has a proper place and workspaces stay clean, accident rates can drop. Spills get noticed and cleaned immediately instead of becoming slip hazards. Tools don't get left in walkways where someone might trip.

Quality improvements follow naturally from better organization. Clean, well-organized environments make it easier to spot problems before they become defects. When workers aren't rushed or frustrated from searching for materials, they make fewer mistakes. The predictability of well-organized processes reduces variability in outcomes.

Perhaps surprisingly, employee engagement often increases significantly. Teams take pride in maintaining organized workspaces, especially when they participate in regular evaluations and see their scores improve over time. The checklist process gives everyone a voice in work area improvement.

Making Implementation Work

Starting a successful 5S checklist program requires more than distributing forms. Begin with leadership commitment and comprehensive training so everyone understands both the evaluation process and its connection to their daily work experience.

Create area-specific checklists rather than generic ones. A machine shop needs different evaluation criteria than an assembly line or office environment. While core 5S principles remain constant, specific items should reflect each workspace's unique requirements.

Establish regular evaluation cycles: daily quick checks for immediate problems, weekly detailed reviews for improvement planning, and monthly comprehensive evaluations for trend analysis. The crucial element many programs miss is systematic follow-through. Identifying problems only creates value when those problems get solved with assigned responsibility and completion tracking.

The Digital Advantage with FlowFuse

Traditional paper checklists have inherent limitations. Results get lost, data analysis becomes time-consuming, and accessing information from multiple locations proves challenging. Digital solutions eliminate these problems while adding capabilities that paper cannot match.

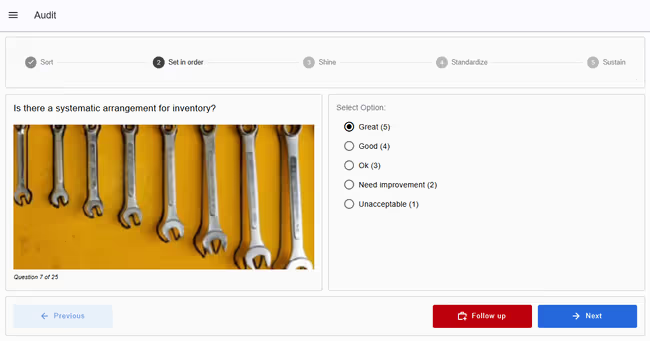

FlowFuse's low-code Node-RED interface makes building sophisticated 5S checklist applications accessible without extensive programming backgrounds. You can create custom evaluation forms capturing exactly the information your operation needs. Simple yes/no questions, numerical scores, or detailed condition comments.

As an industrial data platform, FlowFuse enables seamless integration of 5S checklists into broader operational workflows, connecting work area organization efforts with real-time factory data for comprehensive improvement insights.

Mobile access transforms team interaction with the evaluation process. Workers complete checklists on tablets or smartphones directly in work areas, take photos documenting conditions, and immediately see how current scores compare to previous evaluations. This real-time feedback creates engagement impossible with paper forms.

Sign up for FlowFuse now and get started building your individual 5S checklist.

Up next

If you want to start immediately without creating a checklist from scratch, FlowFuse’s pre-built 5S Checklist Blueprint is ready to use. It includes 25 evaluation questions to assess work area organization, scoring to measure compliance, and follow-up tracking to ensure issues are resolved. The dashboard provides a clear view of improvements over time, and the entire system is fully customizable to match the unique needs of your operations.

Ready to Transform Your Work Area?

Get started with FlowFuse's customizable 5S Checklist Blueprint and build your digital evaluation system in minutes.

Explore 5S Checklist Blueprint →About the Author

Sumit Shinde

Technical Writer

Sumit is a Technical Writer at FlowFuse who helps engineers adopt Node-RED for industrial automation projects. He has authored over 100 articles covering industrial protocols (OPC UA, MQTT, Modbus), Unified Namespace architectures, and practical manufacturing solutions. Through his writing, he makes complex industrial concepts accessible, helping teams connect legacy equipment, build real-time dashboards, and implement Industry 4.0 strategies.

Related Articles:

- Visual Layout Editor - Now Available in Dashboard

- Dialogs, Customizable Icons and Histograms Now Available in FlowFuse Dashboard

- New Layout, Widget and Gauges Now Available in FlowFuse Dashboard

- New Charts Available in FlowFuse Dashboard

- Node-RED Dashboard Formally Deprecated