Scaling Manufacturing Automation with FlowFuse

FlowFuse’s enterprise features complement our broader platform strategy, helping us scale automation and streamline deployments across complex manufacturing environments. The ability to edit once and deploy everywhere has added real efficiency to how we manage integrations.

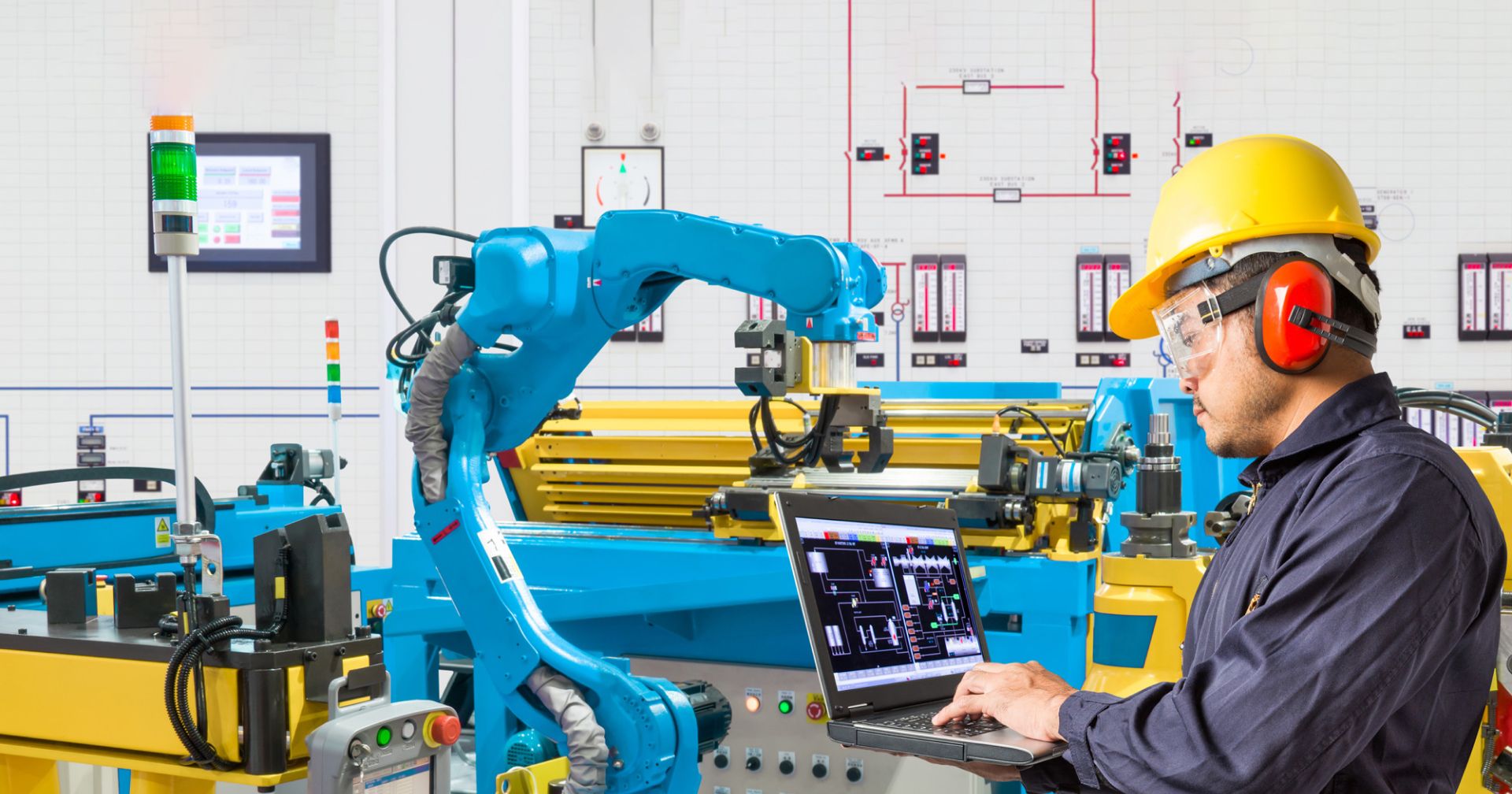

Arch Systems transforms factory intelligence with AI-driven solutions that help manufacturers optimize operations, reduce downtime, and maximize efficiency. Purpose-built for factories by manufacturing and data experts, Arch AI acts as an expert copilot– reading dashboards, synthesizing data, and delivering real-time, prescriptive guidance to operators, engineers, and executives without costly infrastructure overhauls. By leveraging AI to unlock insights from existing factory systems, Arch enables manufacturers to scale expertise, improve critical KPIs, and drive measurable impact on the shop floor.

The Challenge

Arch Systems delivers a manufacturing data and analytics platform that connects complex factory systems, transforms raw production data into actionable insights, and drives measurable performance improvements for manufacturers worldwide. To power this platform, Arch required a reliable and scalable way to integrate with Manufacturing Execution Systems, connect to diverse APIs and databases, and manage the flow of live production data to selected third-party and partner solutions. The scope was significant—spanning 100+ databases and multiple production environments—demanding automation that was both efficient and consistently deployed at scale.

Integrating diverse manufacturing systems while ensuring reliable, real-time data processing is inherently complex. Without the right approach, solutions can become fragmented, difficult to maintain, and challenging to scale across a growing customer base. Arch addresses these challenges by combining its own advanced platform capabilities with trusted partner technologies to deliver unified, high-performance solutions for global manufacturers.

The FlowFuse Solution

Arch Systems incorporates FlowFuse as part of its broader technology stack to enhance automation capabilities, supporting customers’ manufacturing connectivity needs in three key areas:

Real-Time Data Processing Pipeline

Arch Systems implemented MQTT brokers to connect directly to MES systems, creating a reliable pathway for live production data. They configured Node-RED flows to receive and filter this data, then created automated task generation using the processed manufacturing information. This architecture enables immediate response to production events and real-time insights.

Scalable Architecture

The Arch team connected to more than 100 databases, ensuring consistent data ingestion across diverse environments. To streamline how this data was processed within the platform, they built standardized Node-RED subflows that automated job creation in Arch React. These reusable subflows eliminated the need to configure each deployment manually, allowing the team to replicate and tailor workflows quickly for new customers and greatly accelerate implementation.

DevOps Integration

FlowFuse enabled Arch Systems to establish streamlined deployment pipelines with single-point editing and automatic propagation to all production instances. This centralized approach reduced deployment complexity and potential configuration errors while enabling them to make improvements once and deploy them everywhere.

Key Results

- 100+ Databases Connected Through Automated Flows – Arch connected over 100 manufacturing databases using standardized Node-RED subflows, powered by FlowFuse orchestration.

- Faster, Repeatable Deployments – Reusable FlowFuse-managed subflows eliminated manual configuration, allowing Arch to replicate workflows for new customers in a fraction of the time.

- Consistent, Real-Time Data Processing – Combined MQTT pipelines with FlowFuse-managed Node-RED environments to ensure reliable, real-time data streaming across diverse systems.

- Centralized DevOps Control – FlowFuse’s single-point deployment enabled Arch to push updates and improvements across all production environments simultaneously.

- Scalable Automation Framework – The joint solution established a robust, reusable architecture that accelerates onboarding for new manufacturing customers.

Technical Architecture

The solution architecture includes MQTT integration for direct connection to manufacturing execution systems, Node-RED processing for advanced data filtering and transformation capabilities, and automated task creation that dynamically generates tasks based on real-time production data. Multi-environment deployment ensures consistent behavior across development and production environments.

Looking Forward

Arch Systems continues to expand its automation platform capabilities, incorporating FlowFuse’s enterprise features alongside other partner technologies to serve more manufacturing customers and integrate a wider range of data sources and third-party platforms.

Challenge

Connect and automate live production data from multiple databases across global manufacturing environments—without adding operational complexity.

Solution

Arch built standardized Node-RED subflows within FlowFuse to automate job creation in Arch React, streamlining real-time data processing and deployments.

using:

Results

- Reliable, real-time production data ingestion and processing

- Centralized DevOps pipelines simplified updates across environments

- Scalable automation framework enabling rapid new-customer rollout