Building a Label Scanner with FlowFuse for Product Labels & Serial Numbers

A practical guide to automating text recognition in manufacturing workflows

In production environments, labels are everywhere! Products have Serial Numbers and Lot Codes, Packages have Batch IDs and Dates. These are often critical to the processes for packaging, tracking, logging, inventory and so on.

Many companies still do this manually. Someone types in each code as products move through the line. It's repetitive, time-consuming work - mistakes are inevitable.

That's where OCR comes in. Optical Character Recognition (OCR) uses cameras to automatically read and extract text from labels and product markings. Instead of manual data entry, a camera simply captures the image and the system pulls out the information you need. It's a straightforward solution that's already being deployed in modern manufacturing facilities worldwide.

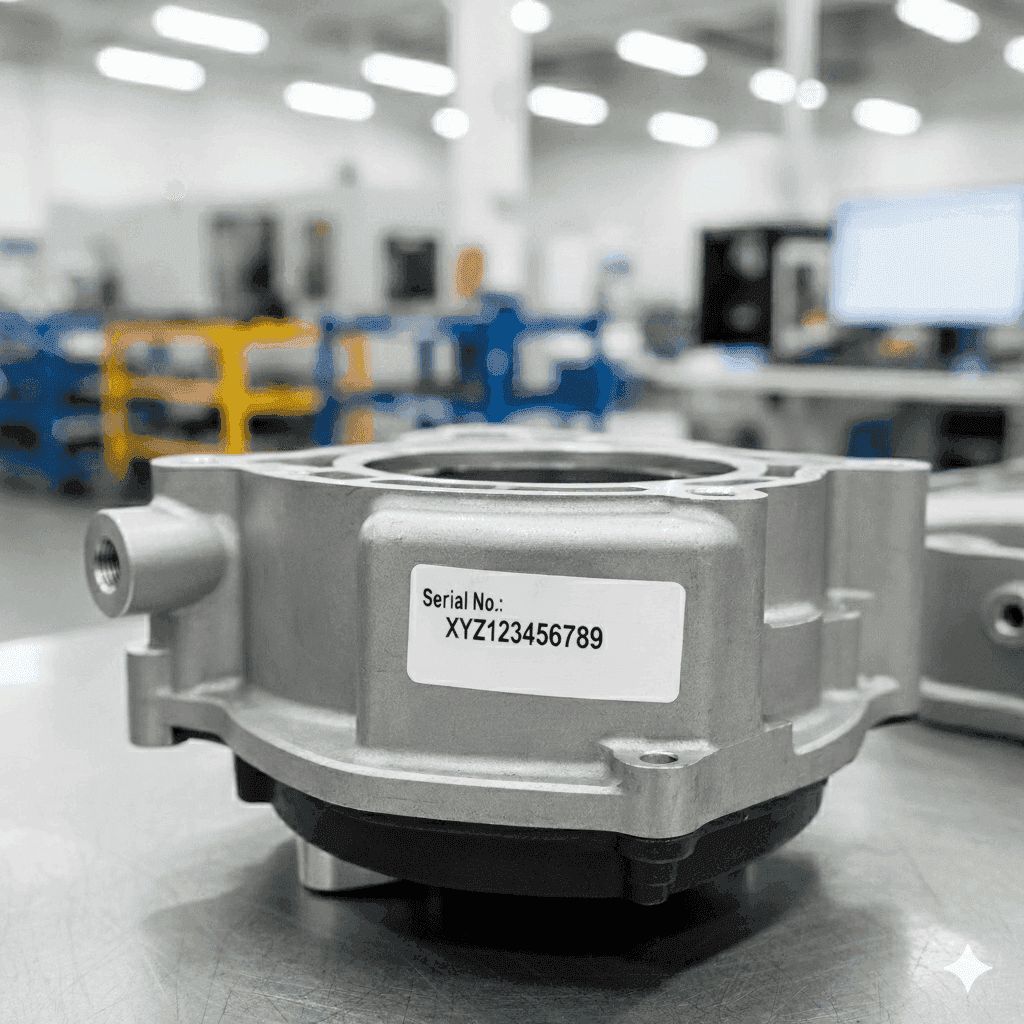

For example, take a look at the image above. When processed with OCR, it returns the following text:

Serial No: XYZ123456789

This tutorial shows you how you can build an OCR system using FlowFuse that can capture images from cameras, extract text from product labels, lot codes, and serial numbers, validate and parse the extracted data, store results in a database or trigger downstream workflows.

Getting Started

Before we dive in, make sure you have a running FlowFuse instance. If you do not have one yet, you can sign up for the 14-day free trial and get a hosted instance running in under two minutes.

Installing Required Nodes

To perform text extraction from images, you’ll need to install the @sumit_shinde_84/node-red-contrib-simple-ocr node in your FlowFuse instance. This node uses the Tesseract OCR engine under the hood to recognize text from image files or image buffers. To capture images and build a dashboard, you’ll also need the FlowFuse Dashboard and Webcam packages.

-

Open your FlowFuse editor.

-

From the main menu, select Manage palette → Install.

-

Search for and install the following packages one by one:

@sumit_shinde_84/node-red-contrib-simple-ocr@flowfuse/node-red-dashboard@sumit_shinde_84/node-red-dashboard-2-ui-webcam

Once installed, you’ll see the simple-ocr node under the Function category and the Webcam widget under the dashboard 2.0 category in the left sidebar.

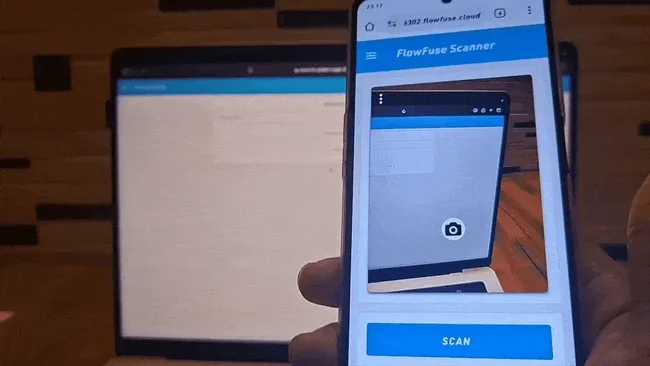

Building the Scanner

Now, let’s build a scanner dashboard that you can open on a mobile device, allowing the phone to act as a scanner for capturing product labels and serial numbers.

To capture images directly from your browser, you can use the FlowFuse Dashboard along with the Webcam widget, let's install them first.

Configuring the Webcam Node

- Drag the Webcam widget onto your canvas.

- Double-click the node to open its configuration.

- Create a new ui group for it to render the feed (for example, OCR Scanner).

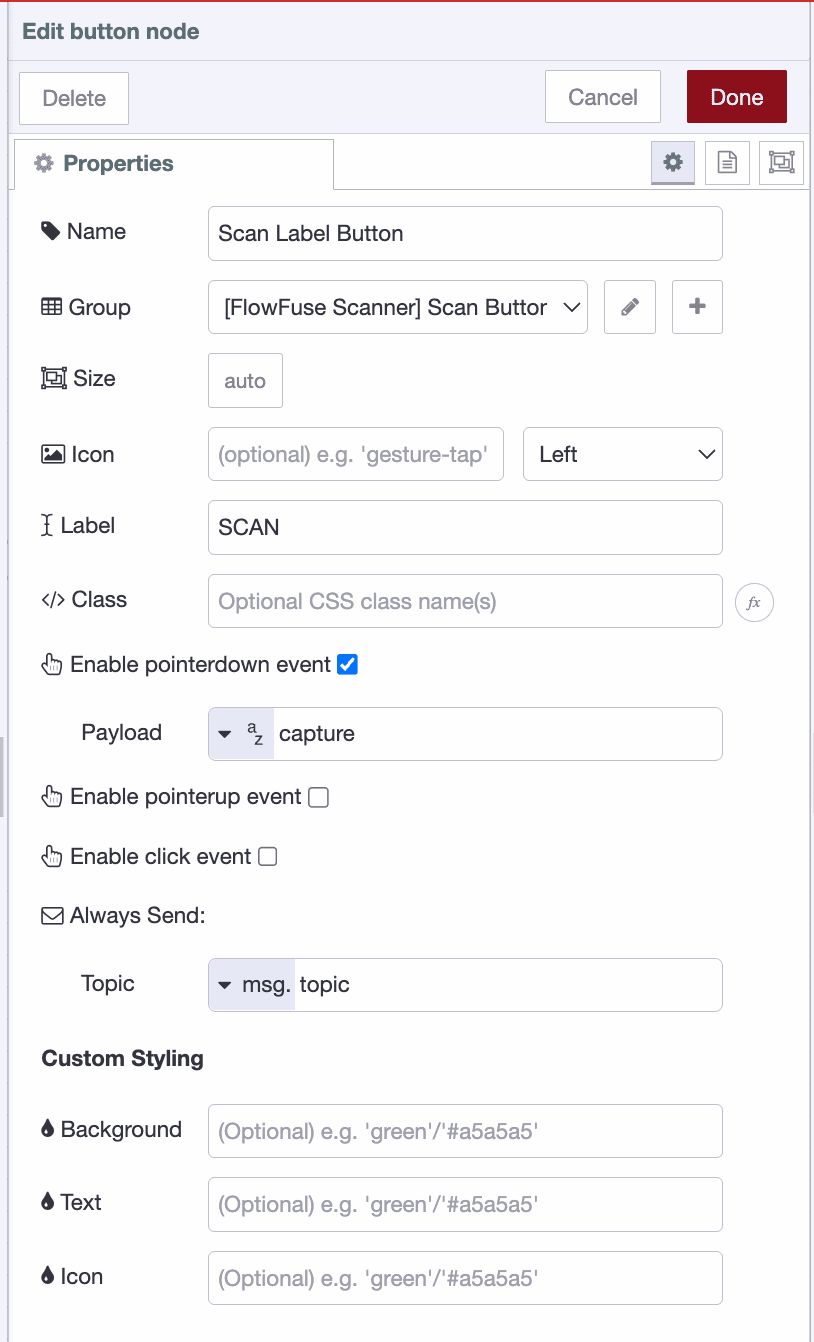

- Drag the Button widget onto the canvas and set its label to Scan. Select the appropriate group, check Enable pointerdown event, and set the payload to

"capture". - Click Done. When the button is clicked, it will send the

"capture"payload, which will trigger the Webcam widget to capture an image.

- Deploy the flow

When deployed, this flow creates a dashboard interface with a live camera preview and a large Scan Label button. Each time you click Scan Label, the captured image is sent as a msg.payload.image containing a image buffer.

Tip: To correct a flipped or mirrored camera preview, open the three-dot menu (⋮) on the webcam widget and enable "Mirror Image".

Handling High-Resolution Images

When capturing an image, if you encounter an error stating that the image size exceeds Dashboard 2.0’s maxHttpBufferSize, you’ll need to reduce the image resolution or quality — otherwise, the dashboard connection may reset.

To fix this:

- Double-click the Webcam widget.

- Adjust the image width, height, and quality parameters.

- By default, these are set to 640×480 resolution and 0.8 quality.

You can also check the image size from the webcam output using msg.payload.sizeBytes.

Adding the OCR Node

Now, let’s add an OCR node to extract text from the captured images.

- Drag a Change node onto the canvas and set

msg.payloadtomsg.payload.image. - Drag a Simple OCR node onto the canvas.

- Connect the output of the Webcam widget to the Change node, and then connect the Change node’s output to the Simple OCR node.

- Add a Debug node and connect it to the Simple OCR node to view the results.

- Click Done, then Deploy.

Next, open the dashboard by clicking the Dashboard 2.0 button in the right sidebar. Then, click the Scan Label button — the first click will activate your camera (make sure to grant your browser permission to access it).

Position the label in front of the camera, focus on it, and click Scan again. The recognized text will appear in the Debug panel. Now, you need to validate and trim the recognized text, and add a visual indicator to show a successful scan. Let’s set that up next.

Validating and Parsing the Extracted Text

The OCR node returns raw text that may contain extra whitespace, line breaks, or unwanted characters. Let's add validation and parsing logic:

- Drag another Function node onto the canvas.

- Connect it after the simple-ocr node.

- Add the following code:

// Extract and clean OCR text

let text = (msg.payload.text || msg.payload || "")

.replace(/[\r\n]+/g, ' ')

.replace(/[^\w\s:]/g, '')

.replace(/\s+/g, ' ')

.trim();

// Match part number

let match = text.match(/(?:Part\s*No|No)[:\s]+([0-9A-Z]{6,12})/i);

let part = match?.[1]?.trim() || null;

// Validate format: 6 digits + 2 letters + 2 digits

let valid = part ? /^\d{6}[A-Z]{2}\d{2}$/.test(part) : false;

// Build payload

msg.payload = {

success: valid,

partNumber: valid ? part : null,

timestamp: new Date().toISOString(),

notificationMsg: valid

? `Label successfully scanned: ${part}`

: "Scan failed — Invalid or unreadable label."

};

return msg;Tip: You don’t need to know JavaScript to create a function for validating and extracting the label text you’re scanning — just tell the FlowFuse Expert what you want, and it will generate it for you.

- Click Done.

This function cleans the text, validates that something was detected, and attempts to extract structured data like serial numbers or part numbers using regular expressions.

Adding Visual Feedback

Users need immediate feedback when a scan succeeds or fails. Let's add both visual indicators:

- Drag a Change node onto the canvas and connect it to the validation Function node.

- Configure the Change node to set

msg.payloadtomsg.payload.notificationMsg. - Drag a ui-notification widget onto the canvas.

- Double-click the ui-notification node to configure it:

- Select or create a UI Base configuration

- Set the position to center

- Optionally, configure the timeout duration (e.g., 3000ms for 3 seconds)

- Connect the Change node output to the ui-notification node input.

- Click Done and Deploy the flow.

Now when you scan a label:

- If the scan is successful, you'll see a green notification with "Label successfully scanned: [part number]"

- If the scan fails, you'll see a warning notification with "Scan failed — Invalid or unreadable label"

Your OCR scanning system is now complete! You can test it by opening the dashboard on your mobile device, positioning a product label in front of the camera, and clicking the Scan button. The system will capture the image, extract the text, validate it, and provide immediate visual feedback on the scan result.

If you want to fully automate this process, you can set up a fixed camera positioned where products pass through on the production line. This approach eliminates manual scanning, but it will require proper camera mounting, lighting setup, and trigger mechanisms to capture images at the right moment as products move past the camera.

Furthermore, you can push scanned label data to a database. The easiest way to do this is using FlowFuse Tables, which is a built-in database service managed by FlowFuse. You'll find the query node in the palette that not only simplifies setup by connecting to the FlowFuse Tables database without any setup, it also has access to the integrated FlowFuse Expert, allowing you to generate queries using natural language — no SQL skills required!

What's Next?

You've just built a working OCR system that turns any mobile device into a label scanner. It captures images, reads text, validates the data, and gives instant feedback—all without writing hundreds of lines of code.

This is just the starting point. Your system can grow with your needs: connect it to your inventory database, add support for different label formats, set up multiple scanning stations, or integrate it with your existing ERP system. The foundation is there.

Also, this OCR scanner is just one piece of what's possible with FlowFuse. Imagine connecting all your manufacturing systems—machine data, quality checks, inventory tracking, production metrics—into a unified industrial data platform where everything flows together seamlessly.

FlowFuse helps manufacturers like you break down data silos and build connected, intelligent operations. From shop floor to top floor, your data works together.

See it in action. Book a demo and discover how FlowFuse can transform your entire facility—not just your label scanning.

Or start building today with our 14-day free trial.

About the Author

Sumit Shinde

Technical Writer

Sumit is a Technical Writer at FlowFuse who helps engineers adopt Node-RED for industrial automation projects. He has authored over 100 articles covering industrial protocols (OPC UA, MQTT, Modbus), Unified Namespace architectures, and practical manufacturing solutions. Through his writing, he makes complex industrial concepts accessible, helping teams connect legacy equipment, build real-time dashboards, and implement Industry 4.0 strategies.

Related Articles:

- Modbus TCP vs Modbus RTU: Reliability, Latency, and Failure Modes

- Building an AI Vibration Anomaly Detector for Industrial Motors

- CAN Bus Tutorial: Connect to Dashboards, Cloud, and Industrial Systems

- FlowFuse 2.27: Integrated Editor in Remote Instances & Context-Aware FlowFuse Expert

- Event-Driven Architecture: 99% of Your System Requests Are Worthless